Some Known Details About Welding Table

Wiki Article

The smart Trick of Smaw That Nobody is Talking About

Table of ContentsFascination About SmawA Biased View of SmawThe Of Spot WelderGetting My Welders Near Me To WorkWelders Near Me Things To Know Before You Buy

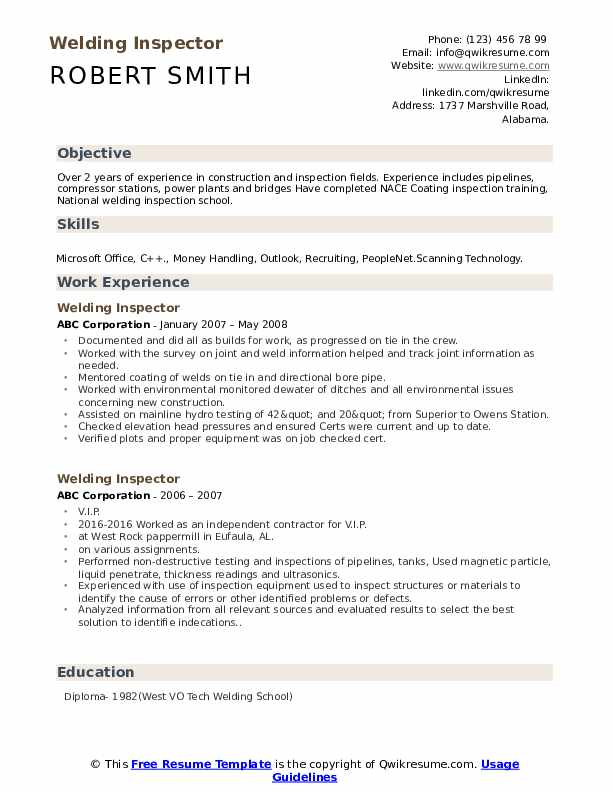

While much of a welding inspector's work is spent in the area making assessments, the opposite of the job is located inside a workplace. This component requires composing reports that will deal with the security and also high quality of the welding that has actually been finished on a given job. Because the examiner's work is to offer a professional opinion regarding whether the welding depends on requirements or otherwise, these records are the basis for legal obligation in situations where defective job triggers crashes or various other problems.The functioning timetable can vary by company and industry, and also irregular functioning hoursincluding evenings and weekendsmay be called for by some employers in this area. Common Companies Welding assessors are most frequently used by firms in the building and construction and production industries. They might examine welds for steel erection companies, or they might inspect welds for business that make airplane and various other metal items.

Little Known Facts About Spot Welder.

Recommendations exist for railways, bridges, and also other specialty frameworks that will certainly permit a welding inspector to add to their resume. For each recommendation that a welding inspector completes, they will obtain a certification noting their successful conclusion of the test as well as an endorsement card. Welding Inspector Income Data We've given you the complying with to get more information regarding this career.This is a 7. 9% change in development over the following 10 years, providing the profession a growth rate across the country of Above Standard. Growth Positions And Realities.

The art of welding entails joining two steels utilizing warm, as well as needs specialized training and skill. Welding, an integral part of our lives, can be seen in many products we utilize every day-- computers look what i found and cars and trucks. Certified welding examiners ensure that welders follow rigorous guidelines and safety policies that maintain both the welder as well as the end individual safe.

Pick your exam website. On the application, applicants must show their first, second and 3rd option for test locations. AWS gives the examinations throughout the year at cities throughout the nation. After confirming the exam website with AWS, applicants can then make travel as well as hotel arrangements. Accomplish education and learning and also work experience demands.

Welding Shops Near Me Can Be Fun For Anyone

AWS uses five-day workshops that help prepare applicants for the test, and also include the exam on the last day. Educating courses cover subjects such as code enforcement, application of documents controling welding inspection and certification, risk-free welding techniques, examination documents as well as devastating testing. Educating courses likewise normally include a hands-on portion that permits trainees to use assessment devices.

Restore your certification every three years. AWS requires that all licensed welding examiners submit a notarized renewal application and the renewal fee of $445 for AWS participants or $660 for nonmembers. AWS does not call for revivals to take any type of tests except the vision test, and also there are no proceeding education demands.

Subjects covered on the test include welding processes, their explanation top quality assurance and math. Prospects require at the very least two years of experience in a welding-related work. Qualified associate welding assessors can just hold their degree of qualification for 3 years, after which they may take the test to get approved for the certified welding assessor credential.

What Does Welding Shops Near Me Do?

Find out just how to come to be a welding assessor. Should I Become a Welding Examiner?Promo to welding inspector might consist of tasks like writing assessment records, guaranteeing that tools complies with engineering, welding as well as screening requirements as well as training various other welding team. Conclusion of a teaching fellowship is one way to get experience in the welding area.

is a liable professional in the welding market completely. Coming to be a welding assessor or licensed welding assessor is an excellent job. Applicants after obtaining licensed by a reputed company like the American Welding Culture have manifold job choices not only in the United States yet additionally in international nations. Getting an AWS qualification is a laborious.

The welding assessor is a specialized career extensively. The vital duties before the welding are as complies with: i. e. (as per the WPS) (in general origin void is 1.

The 7-Second Trick For Cold Welding

5 to 4 mm for pipeline die above 10 inches) as well as click for source (33 to 35 level). Pipe reducing method checking, whether the pipeline is to be thermal cut or mechanically reduced and so on. To is there or otherwise. (as a whole root face is from 1. 6 to 2 mm). (note, if there is preheat on a pipeline then the tack weld should be made after the preheat is done.Report this wiki page